Note on Usage:

- Weld metal is unable to be machined, but it can be ground if necessary.

- Preheat temperature is 150~250℃ for carbon steel, low alloy steel or cast steel base metal.

- Use KCH-615-S for buffer layer.

Chemical Composition & Hardness of All Weld Metal

|

|

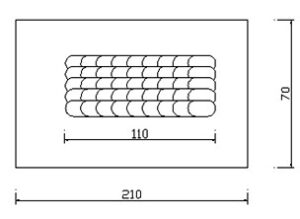

| Specimen specification and welding parameter | |

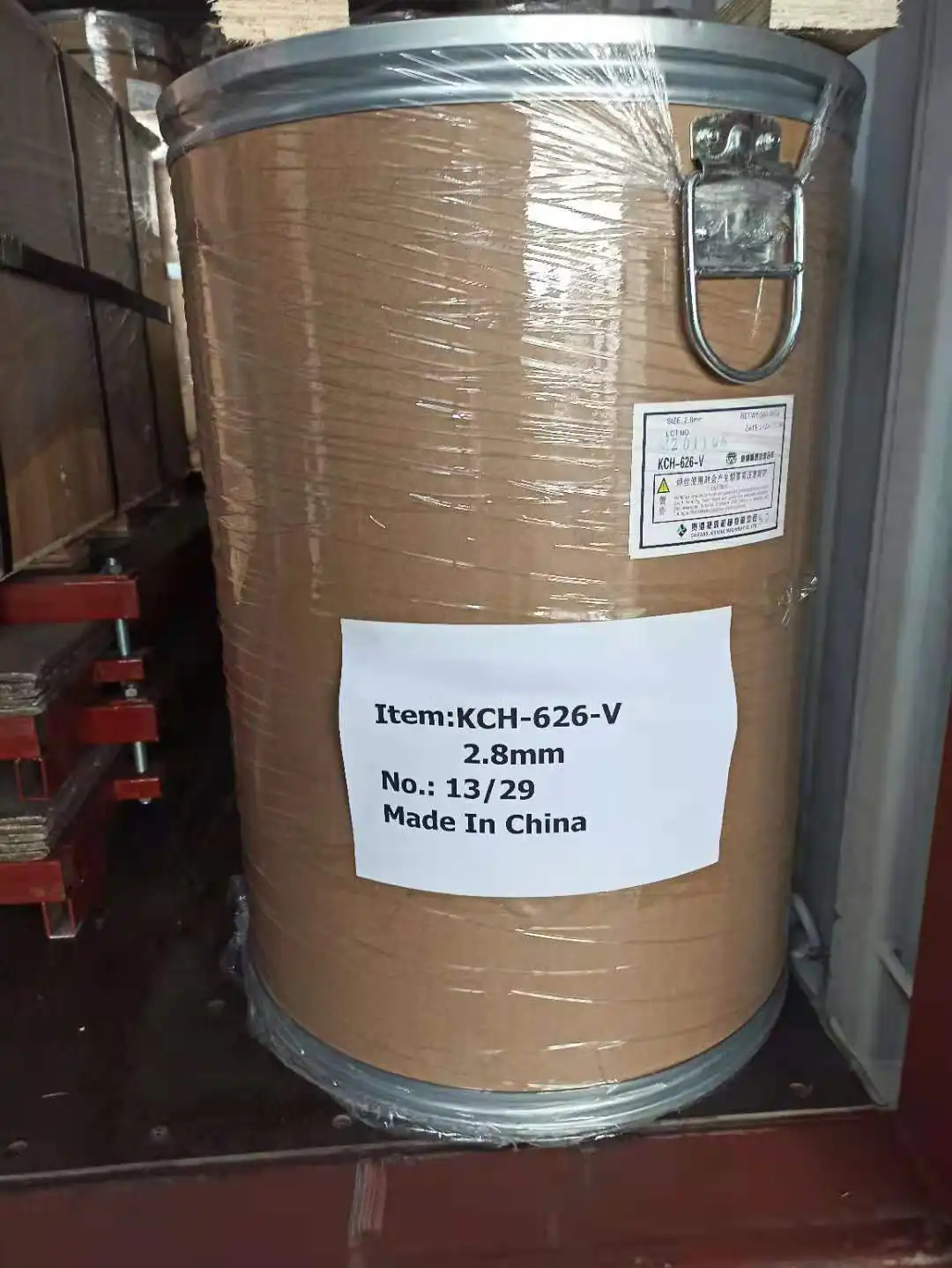

| Diameter (mm) | 2.8 |

| Current (A) | 300 |

| Voltage (V) | 32 |

| Interpass Temp (。C) | 150±15 |

| Shielding Gas | None |

| Polarization | DC(+) |

| Hardness of Weld Metal | |

| Layer | Hardness (HRC) |

| 1 | 55~58 |

| 2 | 57~60 |

| 3 | 58~62 |

| Chemical Composition of Weld Metal | |

| Chemical | unit: wt.% |

| C | 5.2 |

| Si | 1.4 |

| Mn | 0.2 |

| P | 0.016 |

| S | 0.009 |

| Cr | 28.25 |

| Nb | 0.85 |

| Available Sizes and Suggested Operating Range | |

| Size (mm) | 2.8 |

| Voltage (V) | 28~33 |

| Current(A) | 350~400 |

| ESO(mm) | 40~60 |

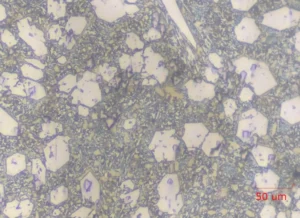

Microstructure of all weld metal

KCH-626-Vproduces a high amount of primary and eutectic carbides. It results in a significant improvement inwear performance.

| This information is provided solely for the purpose of confirming product conformance with applicable standards. The serviceability of a product or structure utilizing this type of information is and must be the sole responsibility of the builder/user. Many variables beyond the control of JIE SHENG MACHINERY CO., LTD. affect the results obtained in applying this type of information. These variables include, but are not limited to, welding procedure, shielding gas, plate chemistry and temperature, weldment design, fabrication methods and service requirements. |